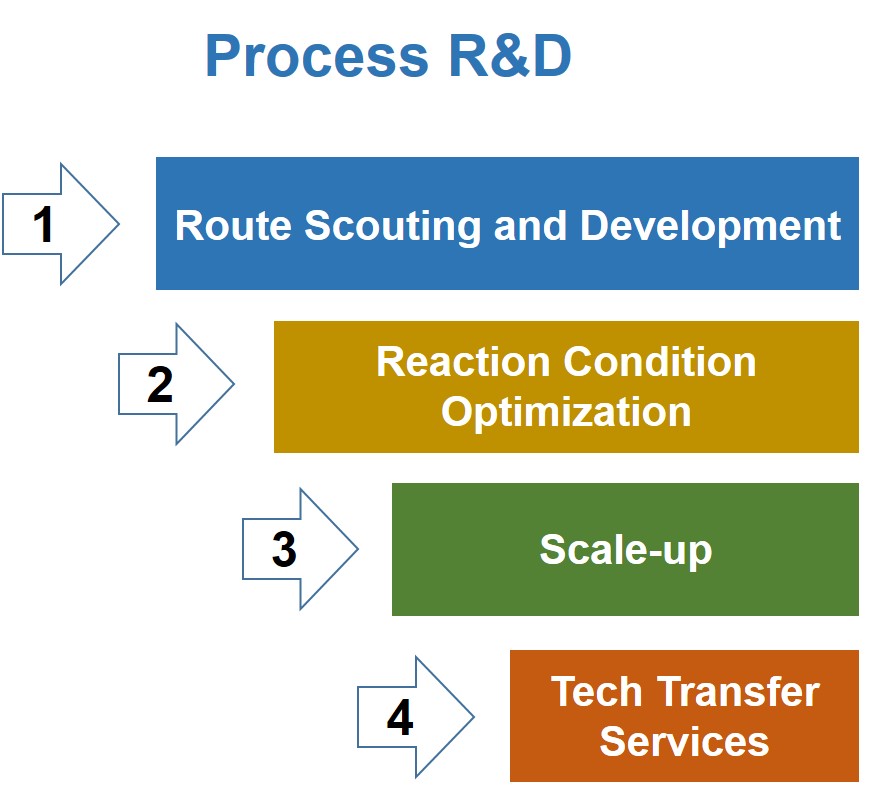

BOC Sciences's professional R & D team is experienced in process optimization, development of new, safe and environmentally friendly process routes. We have a complete one-stop process R&D capability to ensure smooth transfer of process technology and production scale. We make use of resources, equipment, and facilities to provide customers with satisfactory R&D services, saving customers time and costs.

About 30 years ago, "Process R&D" in the pharmaceutical industry only refers to make a chemical process scalable. With the growing awareness of the need to change and develop more efficient processes "Process Research" emerged. The effective Process R&D is important for the growth of a business as well as controlling costs. Process R&D is essential to meet the changing requirements of customers and stay ahead of competitors by introducing new and improving existing products.

With the development of new compound synthesis methods, more technologies emerged in the field of drug discovery. A right and viable synthetic route is required for drug discovery project. With access to the latest literatures and references at reputed libraries and keeping up with latest development, our chemists are working on designing novel, economic, and scalable routes to meet customers' high demands.

The optimization of drug development and manufacturing process is increasingly important since new drugs are constantly emerging on the market. In the development of pharmaceutical chemicals, improving product yield, reducing waste and cost can be achieved by optimizing reaction conditions. Meanwhile, reaction condition optimization is helpful for bringing new chemical entities to market or extending the existing product life cycles.

Scale-up in chemical engineering means the migration of a process from the lab-scale to the pilot plant-scale or commercial scale. The goal of the chemists' work is to minimize the risks of the scale-up of chemistry routes, giving the customers the confidence that their chemicals are viable for commercial scale production.

The chemists in BOC Sciences are experienced in achieving the transformation of knowledge and methods of manufacturing from laboratory to industry. We can offer you all detailed documentation including process description, analytical methods, reports on impurities, and discussion of safety issues.

BOC Sciences has been providing extensive Process R&D services for several decades. Our chemists can efficiently develop scalable manufacturing processes to meet any need. Additionally, according to your needs and the properties of chemical substances, a wide range of custom services are available in our laboratory. Each step of custom synthesis services is subject to BOC Sciences's stringent quality control. Typical delivery specifications include:

What is process R&D in chemical manufacturing?

Process Research and Development (Process R&D) involves designing, optimizing, and scaling chemical synthesis routes to improve efficiency, safety, cost-effectiveness, and reproducibility. It bridges the gap between laboratory research and large-scale production.

What does R&D mean in product development?

In product development, R&D refers to Research and Development—the systematic work undertaken to create new products, improve existing ones, and develop innovative manufacturing processes.

What is pharmaceutical process R&D?

Pharmaceutical process R&D focuses on developing and optimizing synthetic routes, purification methods, and analytical procedures for active pharmaceutical ingredients (APIs) and intermediates, ensuring scalability and consistent quality in production.

What is technology transfer from R&D to production?

Technology transfer is the process of transitioning a developed laboratory procedure into a production-scale process. It involves detailed documentation, process validation, and adaptation of equipment and parameters for larger-scale manufacturing.

What process R&D capabilities does BOC Sciences provide?

BOC Sciences offers comprehensive process R&D services, including route design, reaction optimization, impurity profiling, process safety evaluation, and scale-up support. Our expertise covers a wide range of chemical classes and manufacturing technologies for research and industrial applications.

We deliver process R&D services from design to optimization, integrating innovative methodologies to ensure robust, reproducible, and scalable production.

Submit your inquiry to request a custom solution.

References

If you have any questions or encounter issues on this page, please don't hesitate to reach out. Our support team is ready to assist you.